Products with high chemical inertia and heat resistance widely used in the environmental sector can be supplied in the form of spheres, saddles or special shapes (honeycomb, cones, rashig, PALL rings…). Traditional ceramic materials are classified based on their intended use, water absorption level and degree of compactness.

For environmental applications there are:

- random ceramic material

- structured ceramic material

The only difference between these two macro-products is their shape, as the first can be supplied as:

- spheres

- saddles

- special shapes (cones, rashig, PALL rings…)

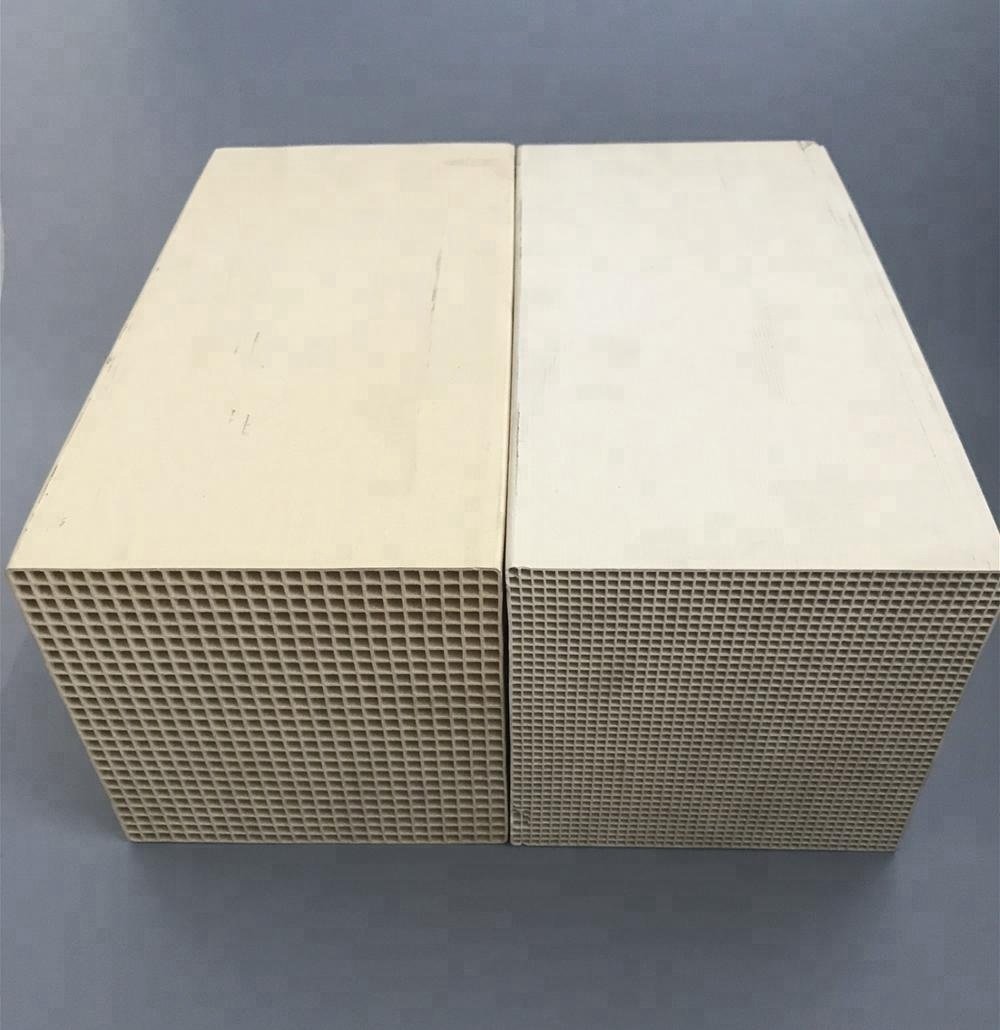

The second are mainly similar to bricks with many holes.

In particular as regards random packings, and specifically for the saddles, we can supply:

| Dimension | ½” | ¾” | 1” | 1 ½” | 2” | 3” |

|---|---|---|---|---|---|---|

| Density [Kg/mc] | 849 | 721 | 673 | 657 | 657 | 480 |

| Vacuum fraction [%] | 63 | 68 | 7171 | 71 | 74 | 79 |

| Specific area [m²/m³] | 505 | 282 | 223 | 148 | 121 | 72 |

While, as far as the bricks are concerned, technically called honeycombs, we can offer the following types:

| Type | 25×25 | 40×40 | 50×50 | 43×43 |

|---|---|---|---|---|

| L*W*H [mm] | 150×150×300 | 150×150×300 | 150×150×300 | 150×150×300 |

| Specific area [ m²/m³] | 540 | 825 | 1005 | 1000 |

| Vacuum fraction [%] | 67 | 65 | 57/64 | 72 |

Ceramic materials properties and applications

- Chemical inertia with regard to biological fluids, and acids

- High resistance to compression

- High thermal inertia

- Low friction coefficient